Device Construction to Demonstrate Cardan Shaft Error

Last year, the norelem ACADEMY supported the sponsorship project “Cardan Shaft Test Setup” at the Munich Technical School with the aim to demonstrate how sensors can detect faults occurring in cardan shafts.

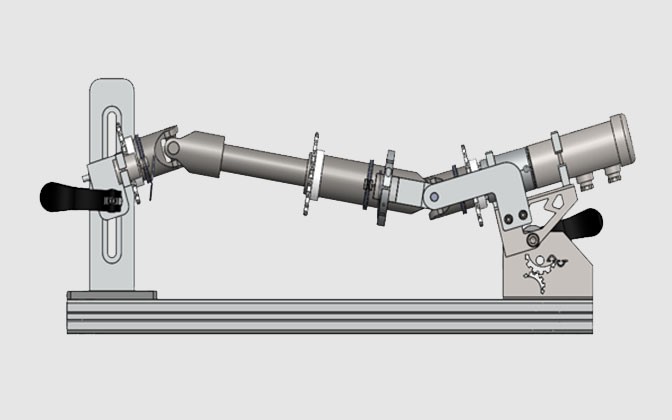

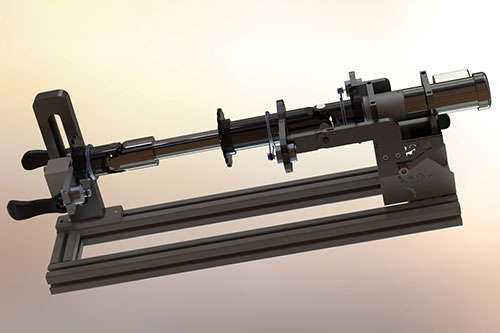

The cardan shaft designed in the funding project is a bearing-mounted cardan shaft with two universal joints, which are driven by a motor with a constant speed. The cardan shaft is to be adjustable in angle and height after production. The requirement for the rotation of the universal joint was considered. The change in length should be made possible by a telescopic rod in the cardan shaft.

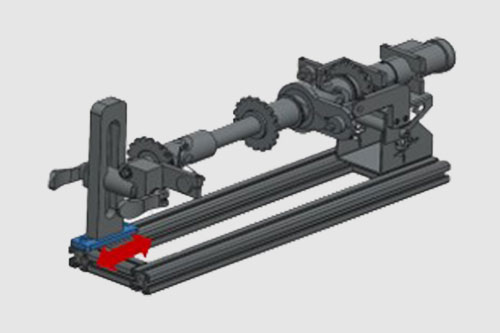

In the project, norelem aluminium profiles and norelem slot nuts were installed. norelem aluminium profiles were used to construct the frame of the fixture. The frame thus forms the basis for fixing the other components of the project to it. norelem slot nuts, enable rapid adjustment in the longitudinal direction.

The frame of the construction with

norelem aluminum profiles:

Longitudinal adjustment with the help of

norelem slot nuts: