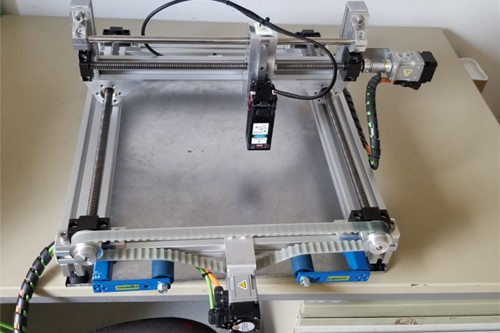

Design and construction of a laser engraving machine

In co-operation with students from the Munich Technical School, we supported the implementation of an idea for the design and construction of a laser engraving machine for engraving wood and other organic materials with our standard and operating parts. The development and construction of the laser engraving machine is particularly interesting due to the variety of interdisciplinary topics.

Requirement for the funding project

The requirement of the project of creating a laser engraving machine was to engrave text and image files on wood and other organic materials to a high quality.

Implementation of the laser engraving machine

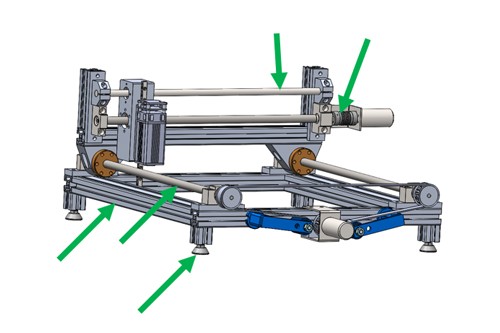

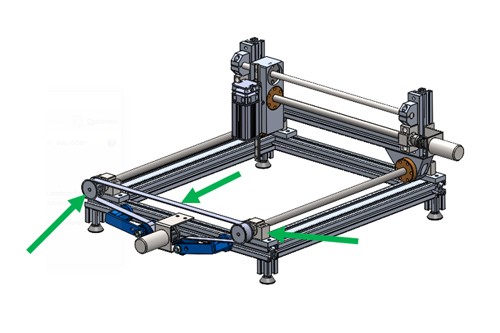

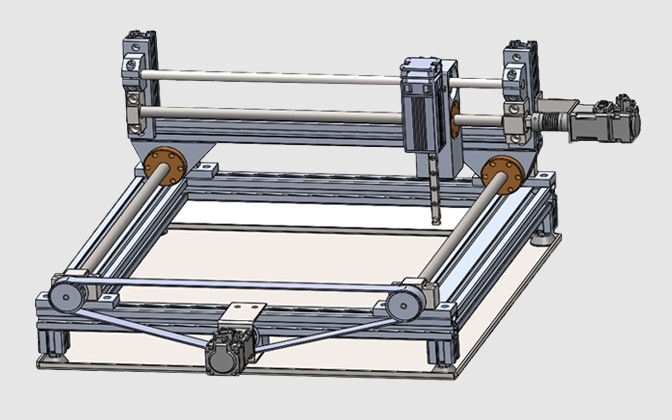

The approach to the technical implementation began with the laser, which forms the heart of the machine. Furthermore, the norelem guides and spindles, the motors and the control unit were integrated. Theoretical as well as practical principles were calculated, and the selection of standard parts was based on the results.

Following this, constructive concepts for the implementation of the partial functions were developed. All these components and sub-functions were transferred into an overall design concept, which was finally built and put into operation.

Use of standard parts

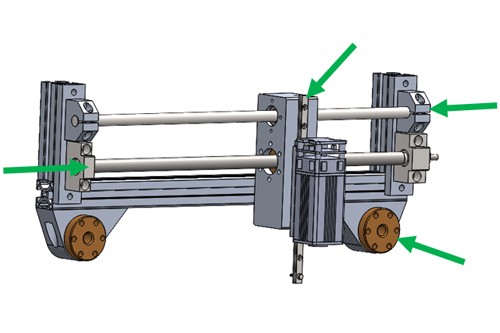

The decision was made to use norelem standard parts because the parts used should be corrosion-resistant, have a long service life and require little effort to adjust the laser. Furthermore, the laser should be guided precisely and stably and dirt should be kept from between the guides. Thanks to the norelem CAD data provided, the selected parts could be quickly and easily installed in the design.

For example, the project produced aluminium profiles for the base frame, trapezoidal spindles and nuts for the X-Y axis, hinge blocks for the trapezoidal spindles, profile guide rails for the Z adjustment, toothed belt pulleys and splined shaft timing belts for the Y drive, metal bellows coupling for the X drive and precision guide shafts were built into the construction.