Plastic shredder/shredder

The increasing consumption of goods is generating ever greater quantities of waste. Packaging waste generated by everyday consumer goods is especially a burden on the environment.

Packaging materials such as cardboard boxes are mostly made from paper, which is easier to break down or decompose than packaging materials made of plastic, synthetic materials, etc. These are difficult to decompose by nature and waste is left behind.

This year, the norelem ACADEMY supported a project at the Carl-Benz-School in Karlsruhe with the aim to develop and produce a shredder machine which can be used for processing waste. The aim is to shred the locally produced waste independently and to reuse the raw materials obtained.

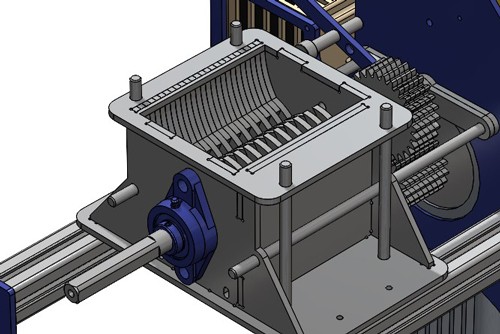

By using standard parts from norelem a smooth assembly could be achieved. Basis for this were the CAD construction data provided during the planning and construction phase. The project was supported by the technical team at norelem, who accompanied the planning and construction phase with their expert knowledge in mechanical engineering.

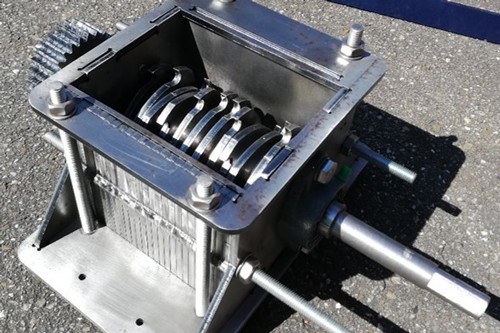

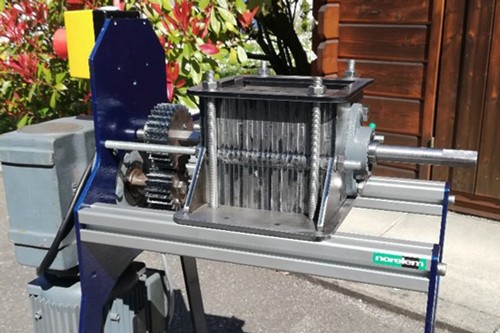

The main element of the machine is the “shredder box”, which is mounted on a frame construction made of aluminium profiles. The plastic waste is fed through the upper opening and shredded in the box by cutting blades sitting on the rotor shaft. The cutting knives are clamped to the rotor shaft with lock nuts to maintain their position even under high loads. The shredded and cut material falls into a collecting container below the “shredder box” and can be further processed later.

In the project, norelem pillow blocks bearing flange type, slotted round nuts and aluminium profiles were used.