norelem moves Viennese mechatronics project

Cyclovent, the innovative table fan

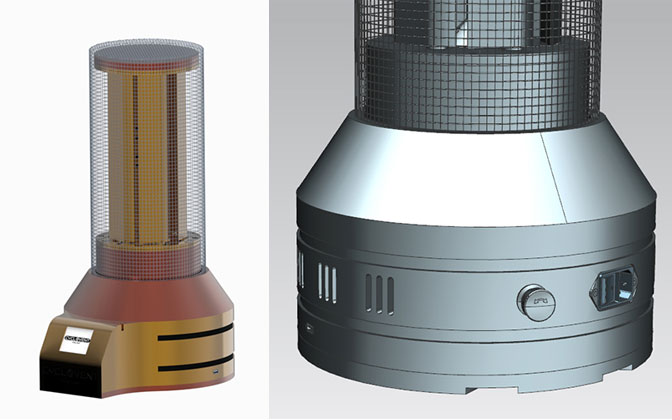

Budding mechatronics engineers at the HTL Rennweg in Vienna have designed a new type of table fan with 360° thrust vector control, the Cyclovent. norelem supported the team of three in building the fan, which has a functional principle based on the Voith-Schneider-Propeller (VSP). The VSP is actually a ship’s propulsion system where blades move on a circular path around a vertical axis of rotation and also perform a pivoting movement. The thrust or its jet area and direction can be continuously adjusted via a display or via the specially programmed mobile phone app. The Cyclovent can thus generate a 360° airflow without a swivel mechanism.

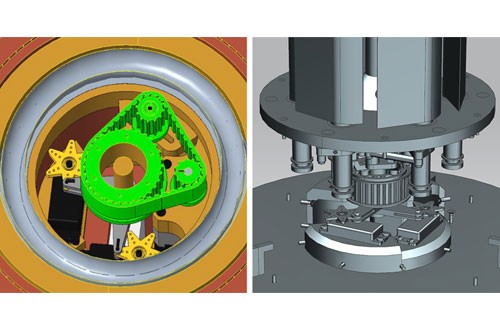

Several components from norelem were used in the construction: The centrally installed toothed belt pulley is supplemented by two other, smaller toothed belt pulleys to be able to tension the toothed belt. Long-life deep groove ball bearings ensure that the tension wheel can rotate freely. Shoulder screws provide axial fixation and allow rotational movement of the connecting rods between the mechanism and the single leaf. Grub screws secure the mounting for the connecting rods. In addition, the Cyclovent has an emergency stop button with which the rotor can be stopped immediately.

The table fan Cyclovent works with a continuously adjustable thrust vector control

and thus generates a 360° air flow without

pivoting. The toothed belt for the drive is

tensioned around three toothed belt pulleys.

Deep groove ball bearings ensure that the

tensioning wheel can rotate freely.

Fitting screws are used for axial fixation and enable the rotational movement of the connecting rod between mechanism and sash. Set screws fix the receptacle for the connecting rod.