Masterly cutting with norelem

norelem supports the construction of a paper cutting machine

Many budding engineers have already had the experience: norelem is committed to promoting young talent and has already supported several mechanical engineering projects with both know-how and components. But not only university students, also prospective master craftsmen have a strong partner for their projects at their side with norelem, as a current, “masterful” example at the Gewerbliche Schule Metzingen shows.

Here, as a practical work, the candidate is tasked to present a tool for his master craftsman’s examination that cuts a DIN A5 paper into 6 cm strips and punches them under certain tolerance specifications. For the construction, norelem provides some standard parts.

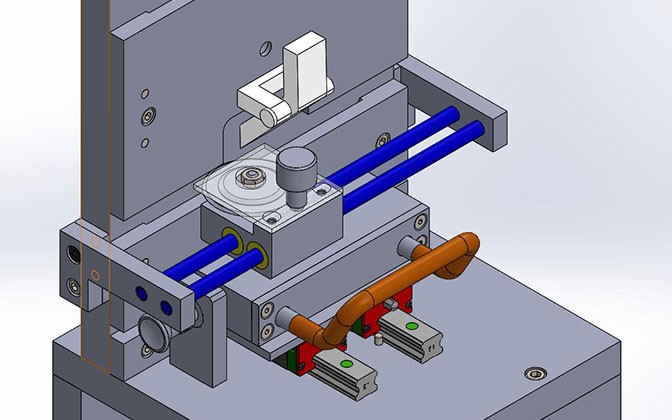

In this so-called “paper cutter”, a piece of paper is placed in the device from above and positioned above the sliding stop. By subsequently operating the angled pull handle, the paper is punched in parallel. With the bow handle, the stop of the paper web can be moved into different positions. After punching, the round knife attached to the knife holder is moved and cuts off the specified paper strip. The combination of linear ball bearings and precision guide shaft ensures that the knife holder runs smoothly, and thanks to the secure guide, a clean cut is guaranteed. By moving the stop, the paper strip finally falls through a recess in the base plate and is collected in a container.

The finished masterpiece, the paper cutter, with bow handle, linear ball bearing and precision guide shaft from norelem. The combination of linear ball bearing and precision guide shaft (both from norelem) can ensure smooth running of the knife holder.

The norelem bow handle operates a pusher that allows parallel punching of the paper web and the paper web stop can be moved to different positions.