Sponsored project: Creation of a milling device

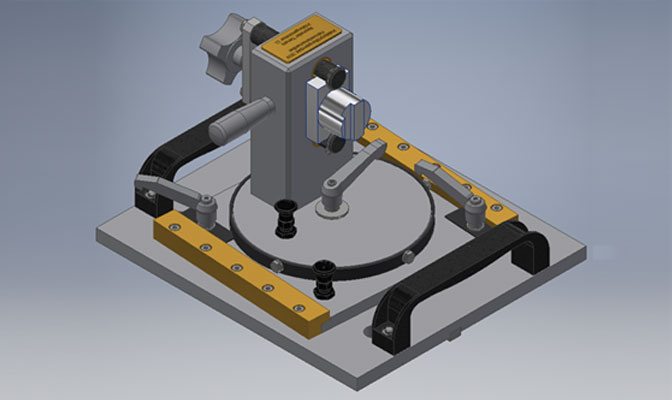

With the support of our standard components, the development of a milling device which makes it possible to mill a specified component with only one moving axis is the goal of a master project of a student of the Chamber of Crafts of Lower Bavaria-Upper Palatinate.

The difficulty here is to design the device in such a way that all three milling operations can be produced by moving or rotating the milling device.

In order to be optimally prepared for the requirements, the student from the Chamber of Crafts received support from the norelem ACADEMY with our standard and operating parts.

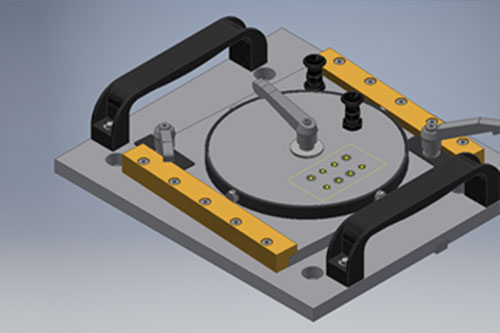

The use of the indexing plungers – premium with tapered pin allows the position of the “round plate” to be set precisely. This allows the required positions to be easily chosen and milled with a very high positioning accuracy. The base plate contains the matching bushes tapered for the locking pin. The clamping lever on the “round plate” ensures fixing and clamping to the base plate.

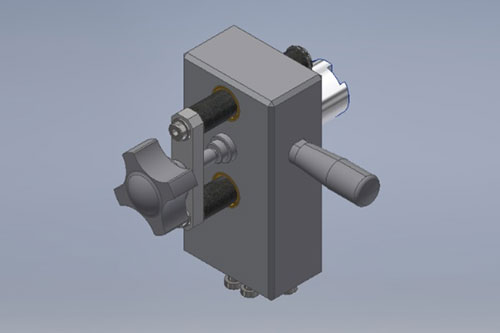

Flat slot keys define the position of the fixture on the T-slot plate. With the norelem thrust screws and the taper grips revolving, the workpieces to be fixed are securely clamped in the milling device, the workpiece is correctly clamped and the forces and vibrations are diverted. The force with which the workpiece is clamped can be optimally adjusted via the torque grips.