Standard and operating parts for farms

The wellbeing of animals, saving of resources and environmental care are the main concerns of the agriculture industry. In order to support family agricultural businesses in the market, we are promoting the “Egg sorting machine” project created by the students of the Technikerschule München with our standard and operating components.

The TH Munich project team

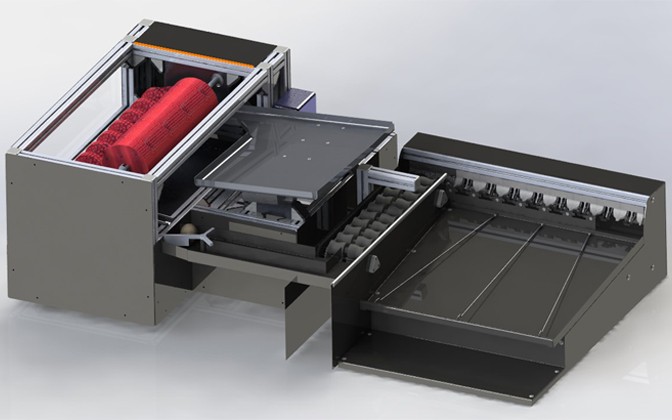

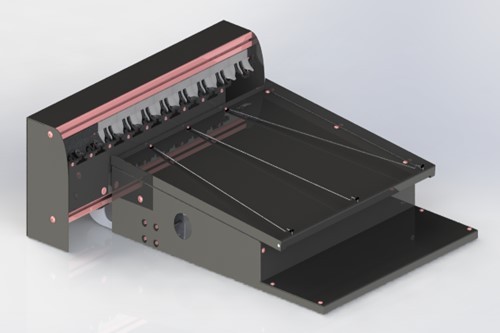

In order to meet the high demand for resources from agriculture and forestry and to plan the production processes from the field to the plate in a way that conserves resources, students at the Munich Technical School developed an egg sorting machine that gently cleans, prints and sorts the eggs in an automated process. The construction of the machine consists of a cleaning station, a screening and printing station and the sorting machine.

Standard parts in the project

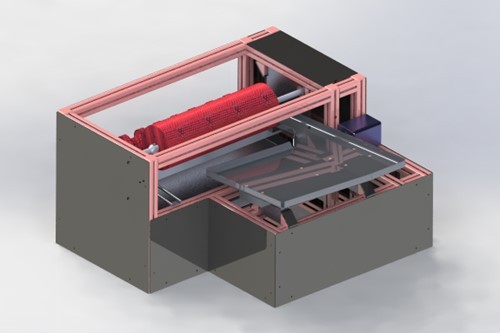

norelem aluminium profiles are the basic frame of the cleaning machine, to which all other components are securely attached.

The eggs are gently freed from feathers, litter and other foreign bodies in the cleaning machine.

norelem profile guide rails with guide carriage are used to set the feed table in motion. This is necessary to ensure a frictionless feed of the eggs into the machine.

In addition, norelem end caps, T-nuts, angle and connecting sets were used.

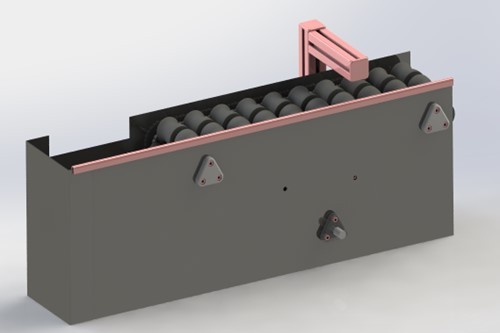

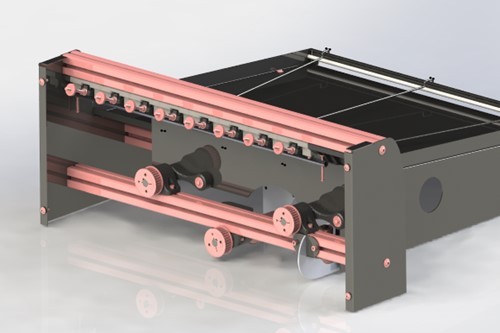

In the screening and printing station, the eggs are aligned horizontally for the further production process. This stage guarantees a further trouble-free process and enables the eggs to be x-rayed in order to detect damage to the shell or foreign bodies.

After the eggs have been inspected, they are printed with the farmer’s producer code and passed on to the sorting unit.

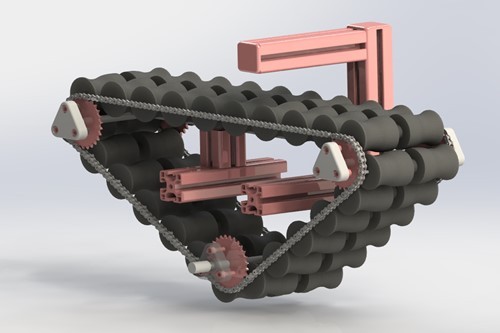

norelem disc sprockets were used in the candling and printing station to transport the eggs on the conveyor belt. The aluminium profiles serve as screw-on points for the printer and the lamp. In addition, end caps, T-nuts and deep groove ball bearings were installed in the fixture.

The sorting station is used to sort the eggs according to their weight and to prepare them gently for further transport.

A norelem beam coupling ensures shock-free running of the grading machine. In addition, possible tension peaks are cushioned.

norelem toothed pulleys, taper bushes and aluminium profiles can also be found in the sorting station.