Support project to improve the safety of firefighters in action

This funding project does not take one’s breath away, but rather is intended to ensure that the air supply for firefighters in action is always guaranteed.

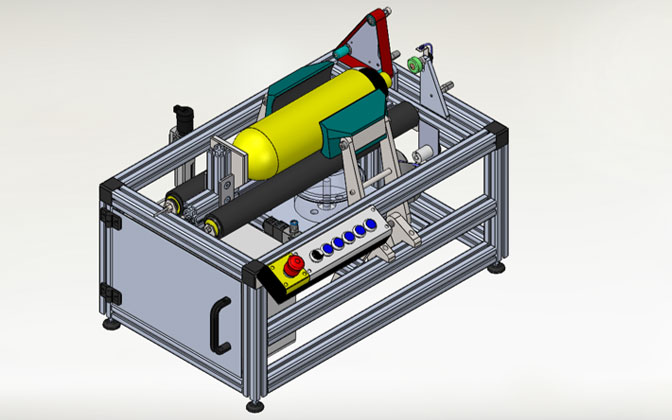

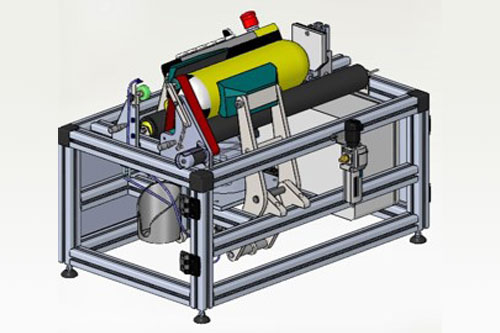

Together with two students from the Munich Technical School, a construction was developed using our standard parts with the aim of improving the safety of firefighters in action. The device for the compressed air cylinder is intended to make it easier for firefighters to prepare for an operation, to save time and thus to concentrate fully on the operation itself.

The greatest danger to firefighters in action are respiratory poisons such as carbon monoxide, hydrocyanic acid, chlorine compounds or hydrochloric acid, which can have a toxic or corrosive effect on the respiratory tract or lungs. To minimise this danger, breathing protection is used that is not dependent on circulating air and is subjected to elaborate TÜV tests every 5 years. Inspected gas cylinders are marked below the neck of the cylinder with a coloured ring, according to the principle of the sticker for the main inspection of a motor vehicle.

Requirement for the funding project

The conveying project or the device for compressed air bottles is intended to help automate precisely this step. To do this, the compressed air cylinder must be fixed in such a way that the valve can be loosened, the old colour marking removed and a new colour marking applied.

As a result of the usage of different materials and dimensions, the following goals arise.

- Place the colour ring in a constant position

- Maximum bottle pressure of 10 N/mm², otherwise the bottle walls will be damaged

- Removal of the old paint marking safely and without residue

- Precise amount of paint for applying the paint mark without the paint dripping or running

- Suction of the sanded paint layer without it being inhaled

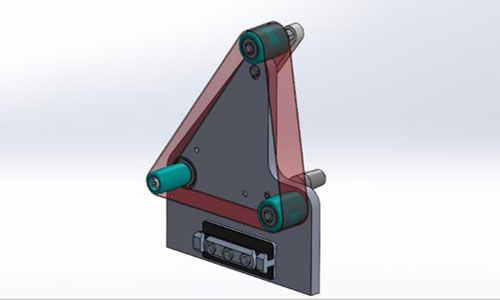

The norelem deep groove ball bearings FAG single row, hinge pins, washers large OD DIN 9021, machine handles fixed straight form, similar to DIN 39, washers large OD DIN 9021 and circlips for shafts DIN 471 ensure the smooth running of the grinding belt and a low starting torque as well as the operation of the component.

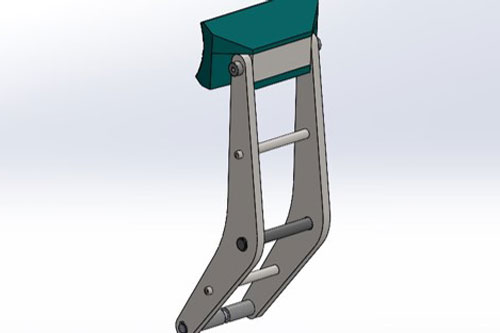

In order for the securing arm of the compressed air cylinders to be clamped/positioned firmly, and to ensure mobility and interchangeability, our norelem plain bearings cylindrical, circlips for shafts DIN 471, shoulder screws similar to DIN ISO 7379, spring plungers, smooth version, self-clamping, plastic and cylindrical pins DIN 6325 were used.

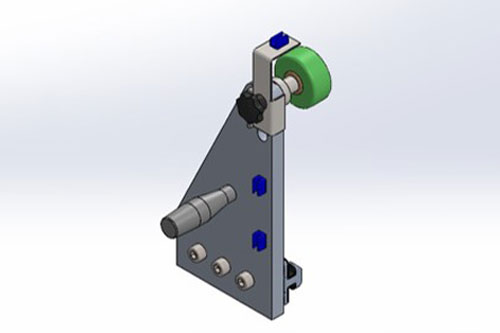

To adjust the position of the paint hose, our standard and operating parts in the form of a star grip similar to DIN 6336, form K with tapped bush and machine handles fixed straight form, similar to DIN 39 – for a pleasant feel for the firefighter in action – were built into the construction.

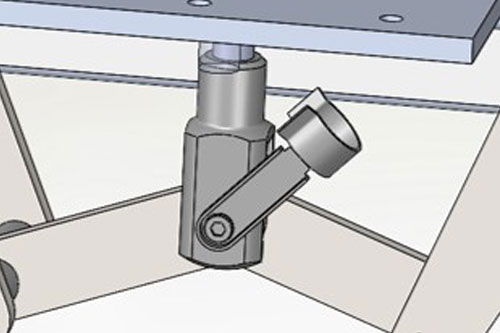

To transmit the force of the cylinder to the clamping device and to facilitate the replacement of the valve, the norelem clevis joints with snap-in pin DIN 71752 spring hinges have been integrated into the design.

In order to ensure that the construction around the aluminium profile system provides the necessary safety for the operator during use, norelem levelling feet round, hinges plastic, pull handles arch, slot nuts twist-in type I and slotted nuts with elastic lock were used in the device. The suction function was realised by means of the norelem suction hoses LOC-LINE® Flexi 75 in order to ensure the safety of the operator during use.

A possible alternative:

To ensure a safe stand and safe operation for the operator, norelem levelling feet round, hinges plastic, pull handles arch, slot nuts twist-in type I and slotted nuts with elastic lock could be used around the aluminium profile system.

In addition, the suction function of the sanded-off paint layers, which could endanger the operator if inhaled, was ensured by the use of norelem suction hoses LOC-LINE® Flexi 75.