A bench with the right twist

norelem supports technicians in the construction of a lathe

With the support of norelem, three young inventors from the Munich Technical College have developed a hobby lathe that can be used to machine wooden workpieces up to a length of 1000 mm and a diameter of up to 500 mm. The drive unit is rotatably mounted so that pieces with a larger diameter do not have to be machined directly above the machine bed.

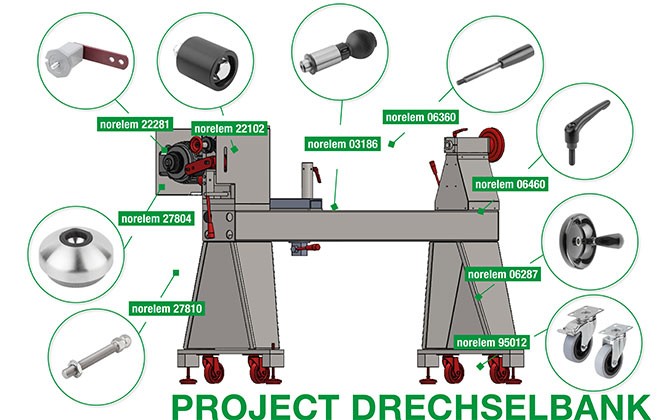

Numerous components from norelem were used in the design. The electric drive, which transmits the rotary movement to the clamped workpiece, is located in the rotating headstock. With the precision indexing plunger from norelem, the drive unit can be brought precisely into the home position at any time and clamped using the grip rod. A belt transmits the torque with the aid of a clamping element and an attached idler pulley. The spindle in the opposite tailstock can be cranked in and out using the disc handwheel and fixed with the clamping lever. The hand rest attached to the machine bed can also be secured or released using the handle bar and clamping lever. The lathe stands on four articulated feet, consisting of plate and threaded spindles made of stainless steel, which compensate for uneven floors and dampen vibrations. And thanks to the four swivel castors, the lathe can be freely positioned in the workshop or secured against rolling away: there are two swivel castors with stop-fix locking system and two swivel castors without locking system.