Aluminium rail cleaning under control

norelem supports the construction of a chip cleaning plant

At the “Gewerbliche und Hauswirtschaftliche Schule” in Horb am Neckar, technicians have implemented a cleaning system for chips. The purpose of the system is to clean milled raw parts from chips and cooling lubricant in a controlled manner. norelem supported the project with various components, as the company manufactures aluminium rails, among other things, which can be installed in the boot of estate cars and SUVs, for example, to secure items of luggage.

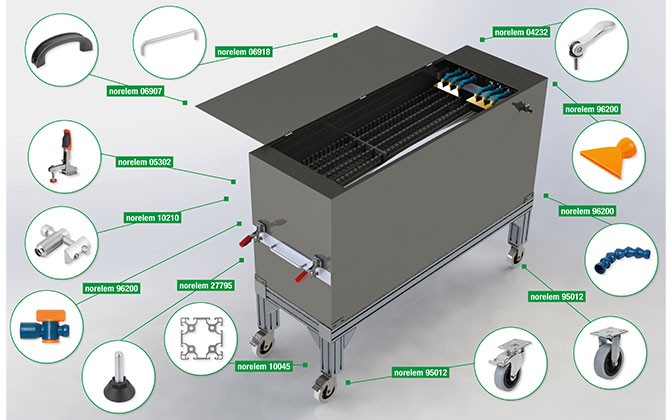

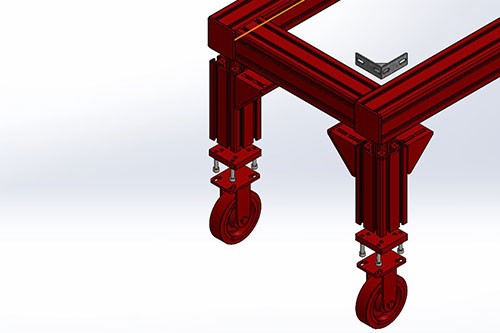

To produce aluminium rails, raw parts have to be milled, which also involves the use of cooling lubricant. After being removed from the milling centre, the parts are usually cleaned of chips and lubricant using compressed air. In order to avoid the noise and chips flying around freely in the future, a closed chamber for controlled cleaning was developed. The cover is equipped with norelem hinges and an arch pull handle for opening and closing, which makes it easy to insert and remove the parts. Standard parts from norelem were also used to equip the cleaning chamber, such as levelling feet, flexible hoses and six flat nozzles, each with a shut-off valve. By means of the flat nozzles, the cleaner can be dispensed in a controlled manner, the articulated hoses allow flexible and quick adjustment. The chip collection container can be easily pulled out with the pull handle and is still held securely in place by variable toggle clamps. The chips are collected in the collection tray and separated from the cleaner. The cleaner is again collected in a tub and can be reused by the integrated pump. Thanks to the stable substructure, the unit has a secure stand even with a total weight of approx. 300 kg and is also mobile thanks to the castors. Four aluminium profiles including angles and end caps, connecting sets and tube clamp were used for the substructure, as well as four foot plates, two fixed castors and two swivel castors with stop-fix locking system.

In the chip cleaning system, milled raw parts can be cleaned under controlled conditions. Standard parts from norelem were used to equip the cleaning chamber – here in the picture the blue articulated hoses with orange flat nozzles.

The chip collection container can be easily pulled out by means of the norelem bow handle and is still held securely by the norelem quick release toggle clamps.

Components from norelem were used for the underframe: aluminium profiles including angles and cover caps, connection sets and tube connectors, as well as foot plates, fixed castors and swivel castors with locking systems.