Textile recycling with ReTex

norelem supports sustainable textile industry project

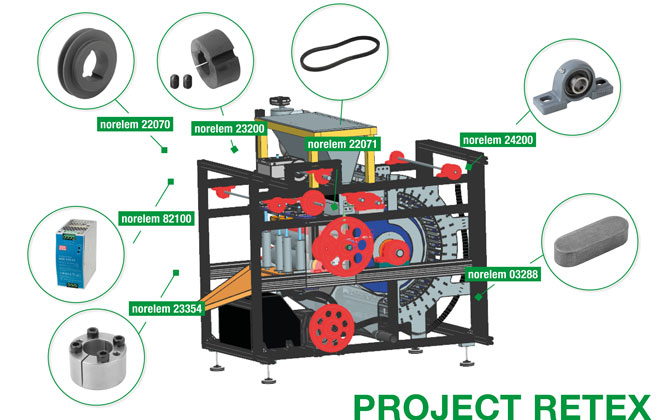

As part of the ReTex project, seven students from the Swiss Federal Institute of Technology in Zurich developed an innovative process for recycling old cotton fabric. The focus here is on gentle fibre opening so that the recovered fibres are not shortened or damaged. The fabrics are first cut to size and loosened, and then gently opened in the specially developed tearing system so that they can be spun back into high-quality yarn. Unopened pieces of cotton are filtered out and returned.

The motor-driven tearing system was realised with the help of numerous norelem components. A V-belt pulley with taper tension bush is attached to the motor. The V-belt pulley absorbs the torque from the motor and transfers forces to the V-belt. The V-belt is held in the correct position in relation to the motor axle by the taper bush. A keyless locking coupling as well as a parallel key ensure a positive shaft-hub connection between the taper tensioning bush and the shaft. Additional V-belts transmit the drive force to the output shaft, which drives the rollers for fabric processing, for example. The pillow block bearing (pedestal bearing UCP) supports the shaft with low friction and keeps it stationary. The switched-mode power supply is used for the power supply and converts the mains voltage from 230 V alternating current to 24 V direct current.