Drinking coffee for science

norelem supports process engineers in the construction of a demonstration plant

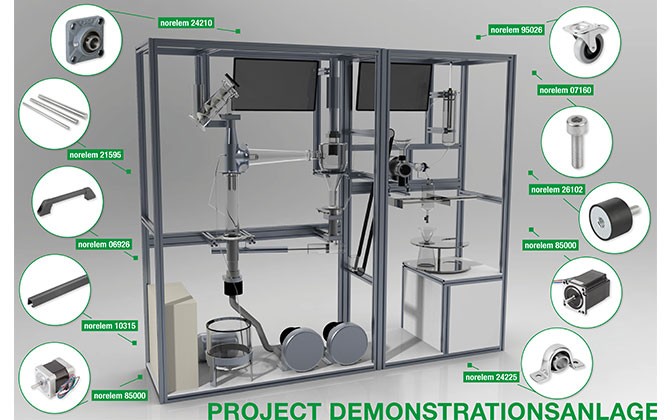

As part of a bachelor’s thesis at the Vienna University of Technology, a “coffee machine 2.0” was constructed that prepares ready-to-drink coffee from green beans. The task and goal was to visualise as many technical processes as possible.

The roasting part of the two-part system contains a fluidised bed reactor for roasting the green coffee beans, a cyclone for separating the silver skins, and a heat exchanger. The extraction part includes a grinder, a heating tank with immersion heater, a suspension tank, and a filtration device.

First, the green coffee beans are dosed via a screw conveyor and roasted in the fluidised bed reactor by means of a fan and air heater

During roasting, water from the tank is pumped through the heat exchanger tube in the reactor to preheat it. The roasted beans are transported to the mill by a bean lift and then ground there. The preheated water is further heated in the heating tank and then sprayed onto the ground coffee with a spray head. Finally, the suspension is filtered off and ready-to-drink coffee is obtained

norelem supported the project with a variety of components. In order to be able to transport the complete plant easily and park it safely, swivel castors with stop-fix locking system and robust tubular handles were installed. Socket head screws and other standard elements were used for the assembly of the fluidised bed reactor. A toothed belt shaft and stepper motor were used to transport the beans to the mill. A pillow block bearing was used for mounting the toothed belt pulley and tensioning the toothed belt. Maintenance-free pillow block bearing flange and a precision guide shaft, precisely controlled by the stepper motor, were installed for the load-bearing, rotating plate on which the coffee is “served” at the end. Any vibrations that might occur were reduced by rubber buffers, and the system was protected from dirt, dust and coffee by cover profiles.

Lockable swivel castors, pipe handles and cover

profiles from norelem are used for safe and clean

transport and operation. norelem cheese head

screws ensure safe assembly of the fluidised

bed reactor.

norelem provides the drive:pillow block bearing

units are used to mount the toothed belt pulley

and tension the toothed belt for transporting the

beans. A stepper motor and a precision guide

shaft enable the movement of the plate on which

the finished coffee is dispensed at the end.