norelem promotes high-speed hovering

Yesterday still science fiction, today already (almost) reality: Hyperloop, the “floating” high-speed transport system. The university group “mu-zero Hyperloop”, founded in 2020 at the Karlsruhe Institute of Technology, is also working on this revolutionary technology. Their goal is to design and manufacture prototypes for the Hyperloop transport concept, with active support from norelem.

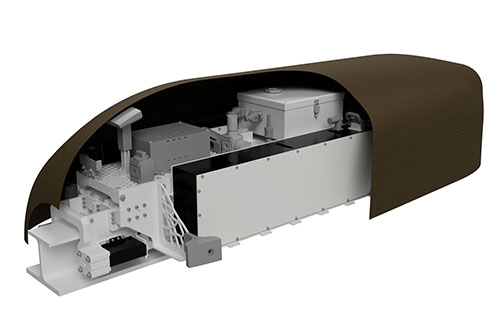

The 60-strong Hyperloop team developed the prototype of a rail-guided transport capsule that moves on air cushions in a largely airless tube, including a novel propulsion system. In the meantime, the capsule has been further optimised and now reaches speeds of up to 109 km/h – a team achievement that is also convincing internationally: at the “European Hyperloop Week” in Delft, the mu-zero group won first place for the best electronic system in 2022. The team also came in the top 5 in the categories of drive, guide mechanism, mechanics and overall system.

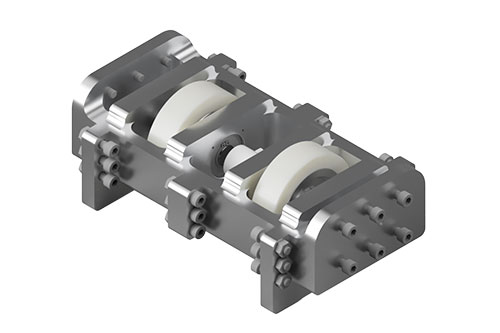

norelem continuously supports the project with know-how and components such as parallel keys and circlips to secure wheels, shafts and bearings. Dowel pins facilitated the exact positioning and assembly of the various assemblies. Elastomer springs and threaded rods ensured proper damping and trouble-free operation.

In the current year, research is again being carried out on new transport concepts – again with the support of norelem. The electromagnetic levitation system is to be converted into a new prototype and realised in a hyperloop system. Parallel to the transport capsule, a new type of rail concept is being developed.

Prototype of the transport capsule

Keyways in the capsule prevent the wheels from turning relative to the shaft; retaining rings fix the wheels axially on the shaft and the bearings in the bearing seats; centring pins at the chassis-frame interface serve for easy, precise installation.